April 25, 2024

|

School of Engineering & Applied Science

Gonzaga engineering and computer science students spend their fourth year working on a real-world project with a team. The projects are all displayed at the Senior Design Expo, an annual spring event where the public at large can see for themselves what these teams collaborated on. This year's Expo happens to align with the celebrations around the 50th Anniversary of the opening of EXPO

‘74, the world’s fair that reshaped the downtown core and championed environmental conservation. Several Senior Design projects emphasize environmental awareness and ecology, and are featured below. The public is invited to meet these students and see these projects amongst the 44 on display at the Senior Design Expo, held Wednesday, May 1 from noon-2 p.m. around the Foley Lawn (next to the Hemmingson Center).

“Design Expo Day is an important milestone in our students’ academic journey,” says Karlene Hoo, dean of the School of Engineering and Applied Science. “To transform innovative ideas into proofs-of-concept and prototypes, our students learned about project planning, communications, report writing, budgeting, and resource management. Taking their ideas from ideation to physical realization, working with industry sponsors, community members, faculty and their fellow students, will serve them well in their careers as they take Gonzaga’s mission of service to others into the workplace.”

The 44 teams of Gonzaga students worked with a total of 31 sponsor organizations, were assisted by a Capstone Committee of GU faculty and a group of 61 Design Advisory Board members; the board consists of experienced professionals who volunteer to provide guidance and mentorship.

“Gonzaga University has long been an integral and respected member of the Pacific Northwest community,” says Ted Zhang, academic director of Gonzaga’s Center for Engineering Design and Entrepreneurship. “Through partnerships with private and public organizations, the Center for Engineering Design and Entrepreneurship seeks to nurture and strengthen ties with local communities, where community leaders pass on their knowledge and share in educating the leaders of tomorrow."

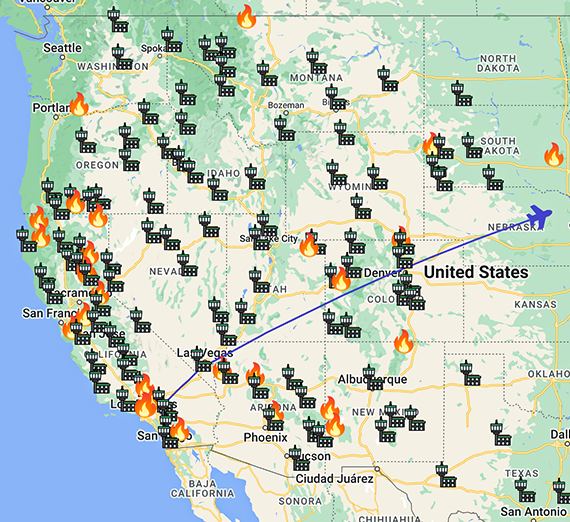

Team 2 – Wildfire Resource Simulator

In the interest of informing the public about aerial firefighting, Fire Armada assigned the CS24-02 team with the task of developing a historical graphic simulation. The simulation depicts wildfires and the flights of large firefighting aircraft in the United States from 2020 through 2022. The project involved developing a web application that features an interactive map and timeline showcasing fires, flight paths of firefighting aircraft, and the locations of tanker bases used for loading fire retardant and refueling. Additionally, the application includes a dashboard that displays statistically-derived graphs and other insightful visualizations.

Team members: Kole Davis, Drew Bogdan, Kevin Dang, Vincent Do, Claire Yegian

Team 21 – Drinking Water System Resilience to Wildfire

The ENSC 24-21 team engaged in the beginning of a five-year research program funded by the U.S. Forest Service evaluating drinking water system challenges and costs for wildfire preparedness in the Western US. They assessed and confirmed the effectiveness of the Eugene water treatment plant post-wildfire impacts, investigated wildfire impacts on treatment processes, and proposed mitigation strategies for water distribution system contamination. The team developed effective testing methodologies and contributed to initial data collection for how to treat wildfire-impacted waters and manage water distribution system contamination.

Team members: Pablo Gomez, Adam Chin, Matt Foley, Noah Hoefer, Mark Chayka

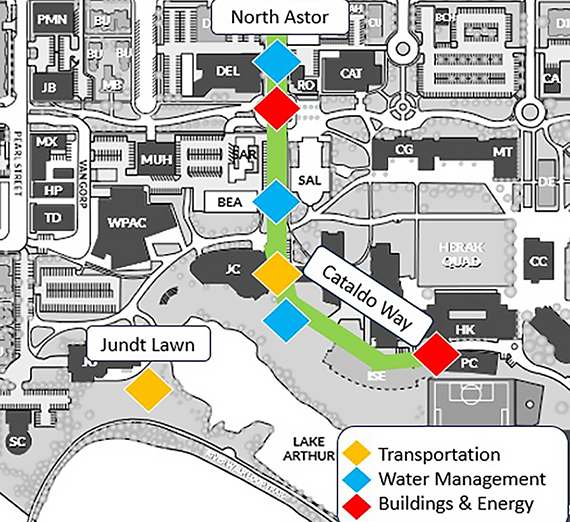

Team 22 – Bringing Netherland’s Sustainable Practices to Gonzaga’s Campus

In the summer of 2022, all members of the team traveled to Delft, Netherlands to study sustainable cities alongside GU Civil Engineering faculty. After their return, Gonzaga tasked EN24-22 with determining solutions to help the campus reach the goals outlined in the Spokane Sustainability Action Plan and the Gonzaga Climate Action Plan. Through reviewing these plans the team identified three areas of focus: transportation, water management, and buildings & energy. The team performed a comprehensive existing conditions study to identify problems in the focus areas on campus that would benefit from implementing sustainable design practices from the Netherlands. EN24-22 developed a conceptual design for the North Astor Street and Cataldo Way corridor that demonstrates stormwater infiltration basins, green facades, and bicycle and pedestrian priority streets.

Team members: Jack Wilson, Joie Reyes, Thomas Roth, Alex Macias

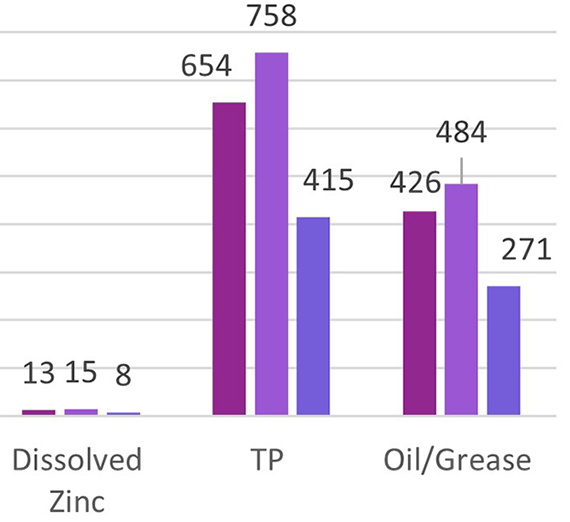

Team 25 – Spokane Stormwater Quality Improvement Study

The City of Spokane is retrofitting stormwater basins with best management practices (BMPs) to capture and treat stormwater. EN24-25 was tasked with prioritizing a stormwater basin for retrofit and to design BMPs. The team determined the criteria to use in evaluating three basins in Northwest Spokane—Rifle Club, Hollywood, and Kiernan Basin. The criteria were organized into a weighted matrix. The team recommended that Rifle Club as the priority basin and designed four different BMPs to present to the City: Rain Gardens, Non-Vegetated Bio-Infiltration, Grass Swales, and Stormwater Planters. Each design is adaptable to various locations in the basin and includes information on cost, construction, operation and maintenance requirements.

Team members: Brynna Bone, Maeve Patterson, Audrey Stevenson, Sarah Simmons

Team 55 – Sustainable Seat Cushion

EN24-55 has worked to decrease carbon emissions and improve sustainability in the aviation industry for Boeing through developing a more sustainable airplane seat cushion. The team analyzed the current seat configuration and proposed suitable alternatives with various advantages. The redesigned seat cushion involves utilizing a sustainably sourced upholstery material, IZIT XRT Faux leather, and a new foam material, Octaspring. Each material provides a reduction in weight, reducing carbon emissions by decreasing fuel consumption. Alongside Kaas Tailored and Adient Aerospace, the team developed prototype cushions. These were subjected to comfortability testing and pressure mapping to qualify the cushions for passenger comfort, and oil burn testing to ensure the proposed design meets FAA regulations and safety requirements.

Team members: Olivia Goodman, Emrie Langfeldt, Nicholas Tudor

Team 56 – Aircraft Interior Parts Recycling

Approximately 90% of an aircraft is completely recyclable at the end of service life. Boeing tasked the EN24-56 team with conducting an industry-wide survey to track the waste streams of the remaining 10%, which is primarily made up of interior parts. After performing the survey, the team chose to focus on alternatives for a large contributor to waste: the interior sidewall panel. The team performed a material analysis on a disassembled Boeing sidewall panel and chose a material replacement for the panel’s body. The team also considered corresponding manufacturing processes. A business case presented the positive environmental impacts of implementing these changes along with an overall cost analysis.

Team members: Elizabeth Anders, Stephen Devine, Faith Duberow

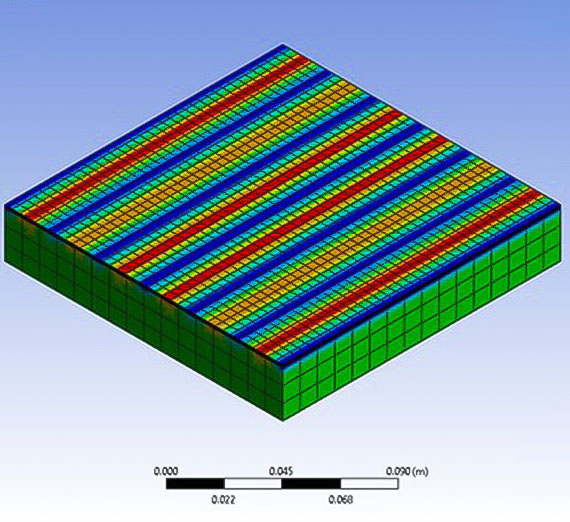

Team 57 – Electric Wing Deicing

Traditionally, airplane deicing is reliant on expensive and environmentally harmful glycol-based fluids. Boeing is interested in finding a better solution. As a part of this effort, team EN24-57 is carrying on a project from last year which includes designing and testing a thermal emitter embedded within the composite wing structure. By integrating thermal emitters into the wing structure, the project aims to streamline deicing processes, mitigate the need for glycol, and improve cost-effectiveness. Leveraging and improving on the previous team’s research, team EN24-57 refined the design via thermal finite element analysis and manufactured the design into a prototype. With the prototype, the team was able to simulate the icy wind conditions and get real world data to support their theoretical testing.

Team members: Benjamin Connors, Erik Dorgan, Caleb Engelken, Jack Morris

Learn more about Gonzaga's Senior Design program